You simply need to know - Basics

Magnetic polarization is a physical quantity. It relates to the electrodynamics of macroscopic matter and characterizes the magnetic flux density of a magnetic material in......

Magnetic polarization is a physical quantity. It relates to the electrodynamics of macroscopic matter and characterizes the magnetic flux density of a magnetic material in a vacuum when the proportion of the magnetic field is subtracted.

Inside the ferromagnet

Ferromagnetic materials consist of many small elementary magnets, also called magnetic moments. They are largely responsible for the magnetization of a material. If they specify a direction of magnetization, one speaks of magnetic polarization. If two magnets differ by opposite north and south poles, this is called reverse polarization.

The symbol of magnetic polarization is J, the associated Unit T (Tesla). Magnetic polarization occurs when an external magnetic field is applied to a material with elementary magnets. Because the magnetic moments then add up, the external magnetic field H0 becomes around the magnetic field constant μ reinforced (corresponds to the magnetic permeability). A magnetic flux density B, which is μ larger than in a vacuum, i.e.

Ferromagnets increase the magnetic flux density. In the external magnetic field, the magnetic polarization is now due to the susceptibility χ.

How can magnetic polarization be measured?

If current flows through a coil and an iron core with a permeability greater than 1 is integrated into its interior, the magnetic flux density at the end of the coil is significantly higher than without an iron core. This is because the spins of the ferromagnetic material align themselves parallel to the external magnetic field. Due to the magnetic polarization, the magnetic flux is considerably larger - the magnetic field becomes stronger.

Because the magnetic moments of ferromagnets have a permanent alignment (due to the exchange interaction), so-called remanence occurs after switching off the external magnetic field, i.e. some of the magnetic polarization remains.

Magnetization, also termed as magnetic polarization, is a vector quantity that gives the measure of the density of permanent or induced dipole moment in a......

Magnetization, also termed as magnetic polarization, is a vector quantity that gives the measure of the density of permanent or induced dipole moment in a given magnetic material. As we know, magnetization results from the magnetic moment, which results from the motion of electrons in the atoms or the spin of electrons or the nuclei. The net magnetization results from the response of a material to the external magnetic field, together with any unbalanced magnetic dipole moment that is inherent in the material due to the motion in its electrons as mentioned earlier. The concept of magnetization helps us in classifying the materials on the basis of their magnetic property.

In physics, a ferromagnetic material is said to have magnetocrystalline anisotropy if it takes more energy to magnetize it in certain directions than in others. These directions are usually related to the principal......

In physics, a ferromagnetic material is said to have magnetocrystalline anisotropy if it takes more energy to magnetize it in certain directions than in others. These directions are usually related to the principal axes of its crystal lattice. It is a special case of magnetic anisotropy.

Causes

The spin-orbit interaction is the primary source of magnetocrystalline anisotropy. It is basically the orbital motion of the electrons which couples with crystal electric field giving rise to the first order contribution to magnetocrystalline anisotropy. The second order arises due to the mutual interaction of the magnetic dipoles. This effect is weak compared to the exchange interaction and is difficult to compute from first principles, although some successful computations have been made.

Practical relevance

Magnetocrystalline anisotropy has a great influence on industrial uses of ferromagnetic materials. Materials with high magnetic anisotropy usually have high coercivity, that is, they are hard to demagnetize. These are called "hard" ferromagnetic materials and are used to make permanent magnets. For example, the high anisotropy of rare-earth metals is mainly responsible for the strength of rare-earth magnets. During manufacture of magnets, a powerful magnetic field aligns the microcrystalline grains of the metal such that their "easy" axes of magnetization all point in the same direction, freezing a strong magnetic field into the material.

On the other hand, materials with low magnetic anisotropy usually have low coercivity, their magnetization is easy to change. These are called "soft" ferromagnets and are used to make magnetic cores for transformers and inductors. The small energy required to turn the direction of magnetization minimizes core losses, energy dissipated in the transformer core when the alternating current changes direction.

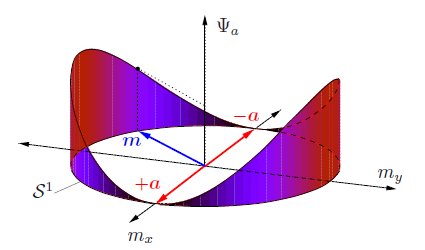

Thermodynamic theory

The magnetocrystalline anisotropy energy is generally represented as an expansion in powers of the direction cosines of the magnetization. The magnetization vector can be written M = Ms(α,β,γ), where Ms is the saturation magnetization. Because of time reversal symmetry, only even powers of the cosines are allowed. The nonzero terms in the expansion depend on the crystal system (e.g., cubic or hexagonal). The order of a term in the expansion is the sum of all the exponents of magnetization components, e.g., α β is second order.

Magnetomotive force, also known as magnetic potential, is the property of certain substances or phenomena that gives rise to magnetic field s. Magnetomotive force is......

Magnetomotive force, also known as magnetic potential, is the property of certain substances or phenomena that gives rise to magnetic field s. Magnetomotive force is analogous to electromotive force or voltage in electricity.

The standard unit of magnetomotive force is the ampere-turn (AT), represented by a steady, direct electrical current of one ampere (1 A) flowing in a single-turn loop of electrically conducting material in a vacuum . Sometimes a unit called the gilbert (G) is used to quantify magnetomotive force. The gilbert is defined differently, and is a slightly smaller unit than the ampere-turn. To convert from ampere-turns to gilberts, multiply by 1.25664. Conversely, multiply by 0.795773.

Although the standard definition of magnetomotive force involves current passing through an electrical conductor, permanent magnet s also exhibit magnetomotive force. The same is true for planets with magnetic fields, such as the Earth, Jupiter, Saturn, Uranus, and Neptune. The Sun also generates magnetomotive forces, particularly in the vicinity of sunspots.

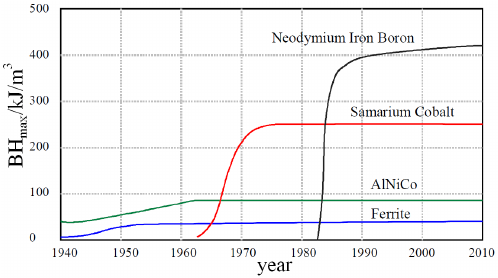

What is the Maximum Energy Product (BH)max?

There are four main indicators for measuring the performance of permanent magnets: remanence, coercivity, intrinsic coercivity, and......

What is the Maximum Energy Product (BH)max?

There are four main indicators for measuring the performance of permanent magnets: remanence, coercivity, intrinsic coercivity, and maximum energy product (BH)max. In the following posts, we will introduce these concepts and their applications one by one. In today’s article, let’s take a look at the maximum energy product (BH)max first.

The maximum energy product (BH)max represents the magnetic energy density established in the space between the two magnetic poles of the magnet, that is, the static magnetic energy per unit volume of the air gap. It is the maximum product of the residual magnetism Br and the intrinsic coercivity Hcj (unit kJ/ m3 or GOe), and its size directly indicates the performance of the magnet.

Magnetic Energy Product Curve

The product BH of the magnetic induction intensity B and the magnetic field intensity H at any point on the demagnetization curve of the permanent magnet is called the magnetic energy product. Its size is proportional to the magnetic energy density of the magnet in a given working state.

The relationship curve between the magnetic energy product and the magnetic induction intensity B is called the magnetic energy product curve. It is a curve obtained by multiplying the value of each point B and H on the permanent magnet demagnetization curve as the abscissa, and the magnetic induction intensity B as the ordinate.

The magnetic energy product reaches the maximum at a certain position in the middle of the demagnetization curve, which is called the maximum magnetic energy product (BH) max. For permanent magnet materials whose demagnetization curve is a straight line, the magnetic energy product is the largest at (Br/2, Hc/2).

The Relationship between Maximum Energy Product & Magnet Performance

For two magnets with the same size, the same number of poles, and the same magnetizing voltage, the magnet with a high magnetic energy product can obtain high surface magnetism.

At the same (BH)max value, the levels of Br and Hcj have the following effects on magnetization:

1. Br is high and Hcj is low: under the same magnetizing voltage, higher surface magnetism can be obtained.

2. Br is low and Hcj is high: to obtain the same surface magnetism, a higher magnetizing voltage is required.

The Maximum Energy Product (BH)max & the Grades of Magnets

The numbers in the grades of NdFeB magnets represent the maximum energy product (BH)max of the product. For example, 38 and 45 in N38 and N45SH represent the maximum energy product of the product as 38MGOe and 45MGOe. The larger the number, the greater the maximum energy product (the letter after the number represents the classification of its intrinsic coercivity, the more backward of the letter indicates the greater the intrinsic coercivity).

The grades of SmCo magnets, such as SmCo16, SmCo18, SmCo24, SmCo26, SmCo28, etc., the numbers also represent the typical value of the maximum magnetic energy product of the product.

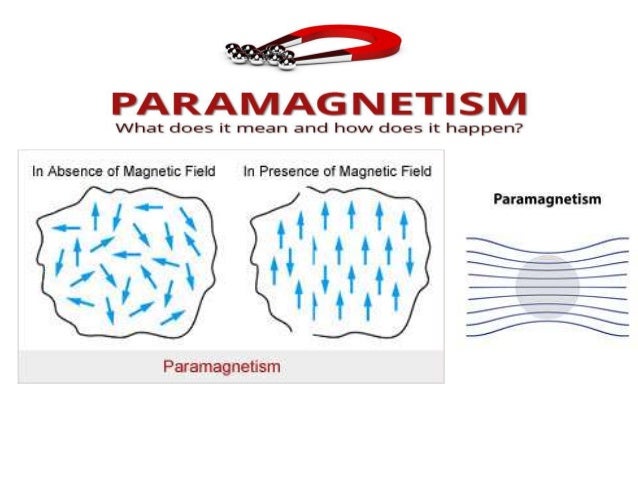

Paramagnetism refers to a property of certain materials that are weakly attracted to magnetic fields. When exposed to an external magnetic field, internal induced magnetic fields......

Paramagnetism refers to a property of certain materials that are weakly attracted to magnetic fields. When exposed to an external magnetic field, internal induced magnetic fields form in these materials that are ordered in the same direction as the applied field. Once the applied field is removed, the materials lose their magnetism as thermal motion randomizes the electron spin orientations. Materials that display paramagnetism are called paramagnetic. Some compounds and most chemical elements are paramagnetic under certain circumstances. However, true paramagnets display magnetic susceptibility according to the Curie or Curie-Weiss laws and exhibit paramagnetism over a wide temperature range. Examples of paramagnets include the coordination complex myoglobin, transition metal complexes, iron oxide (FeO), and oxygen (O2). Titanium and aluminum are metallic elements that are paramagnetic. Superparamagnets are materials that show a net paramagnetic response, yet display ferromagnetic or ferrimagnetic ordering at the microscopic level. These materials adhere to the Curie law, yet have very large Curie constants. Ferrofluids are an example of superparamagnets. Solid superparamagnets are also known as mictomagnets. The alloy AuFe (gold-iron) is an example of a mictomagnet. The ferromagnetically coupled clusters in the alloy freeze below a certain temperature.

There are two main different types of magnet, permanent magnets and electromagnets. A permanent magnet is called a permanent magnet because its magnetism is ‘always......

There are two main different types of magnet, permanent magnets and electromagnets. A permanent magnet is called a permanent magnet because its magnetism is ‘always on’, it generates its own persistent magnetic field unlike an electromagnet which is made from a coil of wire wrapped around a ferrous core and requires an electric current to generate a magnetic field. An electromagnet’s magnetism can be controlled and turned off and on at the flick of a switch as the magnetism depends on a constant flow of electricity.

In addition to permanent magnets and electromagnets there are temporary magnets. Some metals are defined as ferromagnetic, this means that they exhibit their own magnetic properties and are defined as magnetically ‘soft’ materials. Permanent (hard) magnets and temporary (soft) magnets are both ferromagnetic but temporary magnets only display noticeable magnetic properties when influenced by a permanent magnet and tend to not stay magnetised. Magnetically soft materials such as steel conduct magnetism when attached to a magnet but this ceases when the magnet is removed.

How does a permanent magnet work?

How a permanent magnet works is all to do with its atomic structure. All ferromagnetic materials produce a naturally occurring, albeit weak, magnetic field created by the electrons that surround the nuclei of their atoms.

These groups of atoms can orient themselves in the same direction and each of these groups is known as a single magnetic domain. Like all permanent magnets, each domain has its own north pole and south pole. When a ferromagnetic material is not magnetised its domains point in random directions and their magnetic fields cancel each other out.

To make a permanent magnet, ferromagnetic material is heated at incredibly high temperatures, while exposed to a strong, external magnetic field. This causes the individual magnetic domains within the material to line up with the direction of the external magnetic field to the point when all the domains are aligned and the material reaches its magnetic saturation point. The material is then cooled and the aligned domains are locked in position. This alignment of domains makes the magnet anisotropic. After the external magnetic field is removed hard magnetic materials will keep most of their domains aligned, creating a strong permanent magnet.

Permanent magnet strength.

There are several measurements that all contribute to a permanent magnet’s strength, which can often seem confusing. Magnetic field strength (remanence), resistance to demagnetisation (coercivity) and pulling force are all often summarised as strength and all are desired attributes of a permanent magnet. The single primary indicator of a permanent magnet’s strength is its maximum energy product value measured in Mega Gauss Oersteds (MGOe). The higher the maximum energy product value, the greater the magnetic field the magnet will generate in a particular application.

Maximum energy product, also referred to as BHmax is calculated by multiplying a magnet’s remanence (Br) and coercivity (Hc). The strongest magnets in the world are neodymium magnets, which are manufactured in different grades, however, each grade is given a handy name that allows you to instantly judge which magnet is stronger. Commercially available neodymium magnets range from N35 to N52 grade; the number after the letter ‘N’ represents the magnet’s maximum energy product.

A magnet’s individual performance is altered by temperature and some types of magnets perform better at high temperatures than others, such as alnico and samarium cobalt magnets. All magnets lose a percentage of their magnetism per ? rise in temperature and the five types of magnetic material lose magnetism at different rates and have different maximum operating temperatures. If the temperature exceeds the maximum operating temperature of the individual grade it will be permanently demagnetised.

Physical properties.

Most permanent magnets are inherently brittle and should not be utilised as structural components. Dimensions and tolerances vary from manufacturer to manufacturer but most will produce magnets to the tolerance of +/- 0.1mm for all dimensions quoted. Permanent magnets are produced in many shapes such as standard rings, bars and discs plus custom shapes such as trapezoid, arc, mitre and even the ‘top hat’.

Permanent magnets are often coated to improve their performance. Take neodymium magnets for example, they are the strongest permanent magnets available but they are the most prone to corrosion due to their high iron content, therefore they are virtually always supplied with a coating. Typical coatings include, nickel, stainless steel, PTFE (Teflon), epoxy, rubber, gold, titanium, chrome and many more.

Rare earth elements are a group of seventeen chemical elements that occur together in the periodic table (see image). The group consists of yttrium and......

Rare earth elements are a group of seventeen chemical elements that occur together in the periodic table (see image). The group consists of yttrium and the 15 lanthanide elements (lanthanum, cerium, praseodymium, neodymium, promethium, samarium, europium, gadolinium, terbium, dysprosium, holmium, erbium, thulium, ytterbium, and lutetium). Scandium is found in most rare earth element deposits and is sometimes classified as a rare earth element. The International Union of Pure and Applied Chemistry includes scandium in their rare earth element definition.

The rare earth elements are all metals, and the group is often referred to as the "rare earth metals." These metals have many similar properties, and that often causes them to be found together in geologic deposits. They are also referred to as "rare earth oxides" because many of them are typically sold as oxide compounds.

Uses of Rare Earth Elements

Rare earth metals and alloys that contain them are used in many devices that people use every day such as computer memory, DVDs, rechargeable batteries, cell phones, catalytic converters, magnets, fluorescent lighting and much more.

During the past twenty years, there has been an explosion in demand for many items that require rare earth metals. Twenty years ago very few people owned a mobile phone, but today over 5 billion people own a mobile device. The use of rare earth elements in computers has grown almost as fast as cell phones.

Many rechargeable batteries are made with rare earth compounds. Demand for the batteries is being driven by demand for portable electronic devices such as cell phones, readers, portable computers, and cameras.

Several pounds of rare earth compounds are in batteries that power every electric vehicle and hybrid-electric vehicle. As concerns for energy independence, climate change, and other issues drive the sale of electric and hybrid vehicles, the demand for batteries made with rare earth compounds will climb even faster.

Rare earths are used as catalysts, phosphors, and polishing compounds. These are used for air pollution control, illuminated screens on electronic devices, and the polishing of optical-quality glass. All of these products are expected to experience rising demand.

Other substances can be substituted for rare earth elements in their most important uses; however, these substitutes are usually less effective and costly.

From the 1950s until the early 2000s, cerium oxide was a very popular lapidary polish. It was inexpensive and very effective. The recent price increases have almost eliminated the use of cerium oxide in rock tumbling and the lapidary arts. Other types of polish, such as aluminum oxide and titanium oxide, are now used in its place.

Are These Elements Really "Rare"?

Rare earth elements are not as "rare" as their name implies. Thulium and lutetium are the two least abundant rare earth elements - but they each have an average crustal abundance that is nearly 200 times greater than the crustal abundance of gold. However, these metals are very difficult to mine because it is unusual to find them in concentrations high enough for economical extraction.

The most abundant rare earth elements are cerium, yttrium, lanthanum and neodymium. They have average crustal abundances that are similar to commonly used industrial metals such as chromium, nickel, zinc, molybdenum, tin, tungsten, and lead. Again, they are rarely found in extractable concentrations.

Magnetic reluctance is a concept used in the analysis of magnetic circuits. It is defined as the ratio of magnetomotive force (mmf) to magnetic flux. It......

Magnetic reluctance is a concept used in the analysis of magnetic circuits. It is defined as the ratio of magnetomotive force (mmf) to magnetic flux. It represents the opposition to magnetic flux, and depends on the geometry and composition of an object.

Magnetic reluctance in a magnetic circuit is analogous to electrical resistance in an electrical circuit in that resistance is a measure of the opposition to the electric current. The definition of magnetic reluctance is analogous to Ohm's law in this respect. However, magnetic flux passing through a reluctance does not give rise to dissipation of heat as it does for current through a resistance. Thus, the analogy cannot be used for modelling energy flow in systems where energy crosses between the magnetic and electrical domains. An alternative analogy to the reluctance model which does correctly represent energy flows is the gyrator–capacitor model.

Magnetic reluctance is a scalar extensive quantity, akin to electrical resistance. The unit for magnetic reluctance is inverse henry, H−1.

History

The term reluctance was coined in May 1888 by Oliver Heaviside. The notion of "magnetic resistance" was first mentioned by James Joule in 1840. The idea for a magnetic flux law, similar to Ohm's law for closed electric circuits, is attributed to Henry Augustus Rowland in an 1873 paper. Rowland is also responsible for coining the term magnetomotive force in 1880, also coined, apparently independently, a bit later in 1883 by Bosanquet.

Reluctance is usually represented by a cursive capital R.

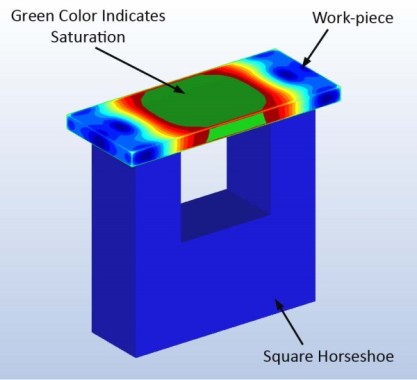

Saturation usually occurs in thinner workpieces where there is less volume of material to act on. Oftentimes, the entire workpiece does not saturate and there......

Saturation usually occurs in thinner workpieces where there is less volume of material to act on. Oftentimes, the entire workpiece does not saturate and there is actually a gradient within the workpiece with only portions being driven into saturation. Even though the entire workpiece does not saturate, the force is still limited because the non-saturating areas are not contributing to the attractive force.

Directly measuring the degree of saturation within a material can be difficult as this is an internal phenomenon. There are, however some first order methods which may indicate a system is in saturation. One option is to inspect the non-working face of the workpiece (the face which is opposite of the externally applied magnetic field) and try to observe any field “leaking” through. The degree of the leakage is a good indicator of saturation and suggests the workpiece would benefit from being thicker. The other option is to increase the workpiece’s thickness and see what effect it has. If one doubles the thickness of the workpiece and receives a measurable increase in attractive force, then the original workpiece was saturating, however, there is a point of diminishing returns. Increasing the thickness of a workpiece is generally always beneficial, but it will impact cost, mass, and possibly ease of manufacturing.

In conclusion:

- Saturation can negatively impact a design by lowering the overall magnetic efficiency of the system.

- Saturation of a material can be thought of the limit at which the material can carry magnetic flux. A pipe analogy works well as there is a limit to the volume of material carried by a pipe a there is a limit of magnet field a material can carry.

- There is a limit to how much induced magnetism is possible in a material. When no more internal magnetism can be created within a material, it is said to be saturated.

- Saturation is a fluid condition which is dependent upon the material’s magnetic characteristics and the intensity and direction of the applied magnetic field.

- Thinner workpieces usually suffer from saturation more than thicker workpieces.

- Magnetic saturation in the workpiece limits the effective attractive force between the workpiece and a magnet.