Down to nanoscale - Properties

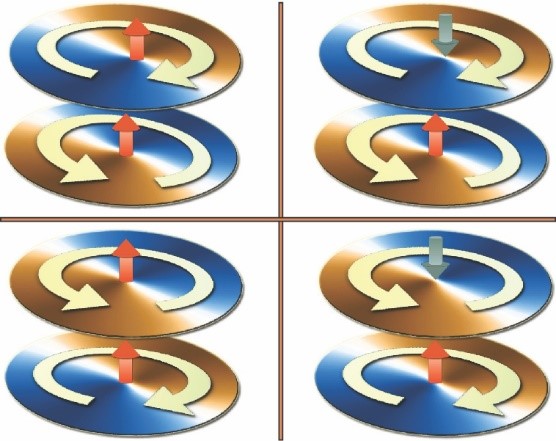

Magnetic dots

Img src

Many other properties of magnetic dots stem from their domain structures. On the one hand, single domain dots tend to have larger coercivities than corresponding continuous films, due to the change in reversal mechanism (e.g., from domain nucleation to coherent rotation) and/or the increase in demagnetizing field. On the other hand, systems with closure domain structure or vortex states will have reduced remnant magnetization. In other words, the magnetization process, and thus the hysteresis loop, may be radically different between dots of different sizes and continuous films of the same material.

Another important property of the dots is the presence of new anisotropies absent in continuous films. There are essentially four such anisotropies: (i) the most important is related to the shape of the dots (shape anisotropy). Strictly speaking shape anisotropy is not a new anisotropy, since it is also present in bulk and thin film ferromagnets.

Article src: Ordered magnetic nanostructures: fabrication and properties, J.I. Martiın, J. Nogues, K. Liu, J.L. Vicent, I. K. Schuller, Journal of Magnetism and Magnetic Materials 256, 449-501, 2003.

Molecular nanomagnets

Img src

Another class of magnetic nanostructures are molecular nanomagnets, sometimes termed single-molecule magnets. Magnetic molecular clusters are intermediate between classical and quantum magnets and show unusual properties. Molecular nanomagnets are mainly organic molecules that are bonded to metals with unpaired electrons. Molecular nanomagnets are promising candidates for observations of quantum phenomena due to their well-defined structure and well characterized spin state. Thermally activated quantum tunneling of magnetization was first observed in molecular nanomagnets.

Article src: Handbook of Nanomaterials, R. Vajtai, Springer-Verlag Berlin Heidelberg, 2013.

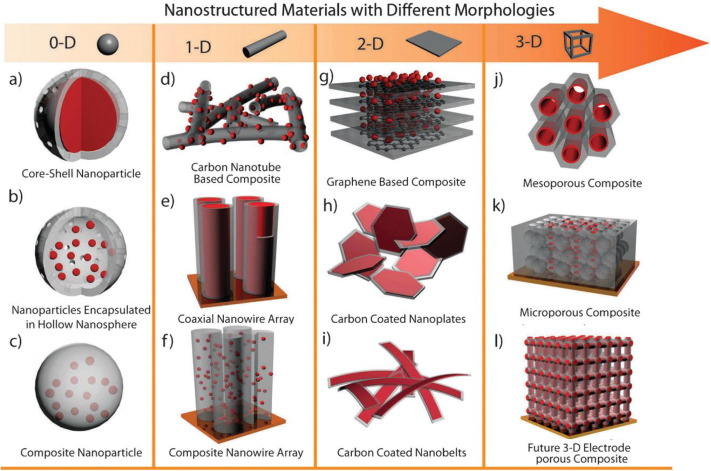

Nanostructured materials

Img src

Nanostructured materials have large surface area to volume ratios, which can result in inhomogeneous magnetic properties. Due to the quenching of orbital moments in the bulk, there is no orbital contribution to total magnetic moment; hence, magnetic moment in the bulk is generally lower than that at the surface. Surface anisotropy also differs from bulk anisotropy, and exchange interactions can vary within the nanostructure. Several methods are used for characterization of structural and magnetic properties of nanostructured magnetic materials.

X-ray magnetic circular dichroism provides information about the local magnetic environment, small-angle neutron scattering (SANS) yields information about the magnetic environment around atoms, and spin polarized scanning tunneling microscopy (SP-STM) also yields data on the local magnetism of atoms at surfaces or interfaces. Magnetic measurements are performed by the same techniques used for bulk magnetic materials, e.g., vibrating sample magnetometry (VSM), SQUID magnetometry, and magneto-optical Kerr effect (MOKE). Magnetic force microscopy (MFM) is used for study of magnetic domains and domain wall motion. Structural characterization is performed by techniques such as scanning electron microscopy (SEM) and transmission electron microscopy (TEM).

Understanding nanostructuring-induced phenomena in magnetic materials such as spin-polarized tunneling and GMR effects requires theoretical study of atomic-scale magnetism, in addition to experimental investigations. Theoretical studies, primarily based on density functional theory (DFT), have been conducted to understand the electronic structure, and methods have been developed to relate ab initio electronic structure calculations with large-scale molecular dynamics simulations to elucidate the magnetic behavior of nanostructured materials.

Article src: Handbook of Nanomaterials, R. Vajtai, Springer-Verlag Berlin Heidelberg, 2013.

Nanowires

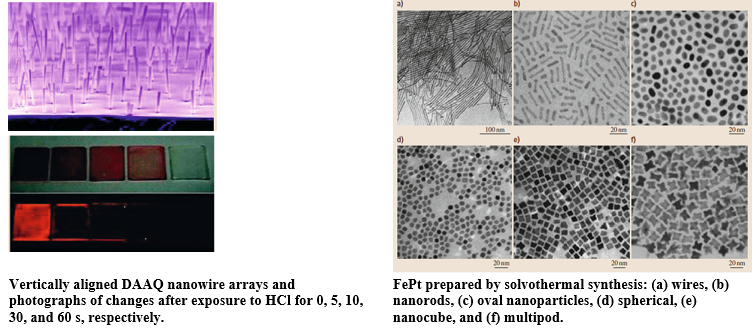

The coercivity/magnetization reversal mechanism of nanowires is different from that of the bulk. The easy magnetization direction of nanowires is along the nanowire axes, and the overall magnetic anisotropy is dominated by the shape anisotropy. Hysteresis loops exhibit greater squareness for fields applied parallel to the nanowire arrays compared with when the applied field is perpendicular. However, researchers observed no significant difference between curves with the field applied parallel or perpendicular to the wires. The magnetization reversal and coercivity of the nanowires are sensitive to the nanowire diameter. Magnetization reversal may occur by coherent rotation, magnetization curling, and buckling.

Shape control of nanoparticles such as nanowires and nanotubes provides an opportunity to tune shape anisotropy. Progress in experimental techniques has made it possible to synthesize nanowires with high aspect ratio. Among the methods used for fabrication of nanowire arrays, template-assisted electrodeposition is a low-cost and high-yield technique, and FePt nanowire preparation by electrodeposition and solvothermal synthesis has been reported; due to the high reduction potential of Nd, however, it is difficult to synthesize Nd2Fe14B nanowires by electrodeposition. In the solvothermal synthesis process, by controlling the surfactant concentration, different shapes and sizes of FePt nanoparticles can be synthesized. Due to the high anisotropy of nanowires, high coercivity of FePt nanowires is expected.

Article src: Handbook of Nanomaterials, R. Vajtai, Springer-Verlag Berlin Heidelberg, 2013.

Article src: Magnetism: Basics and Applications, Stefanita, Carmen-Gabriela, Springer Heidelberg Dordrecht London New York, 2012.

Quantum dots

Img src

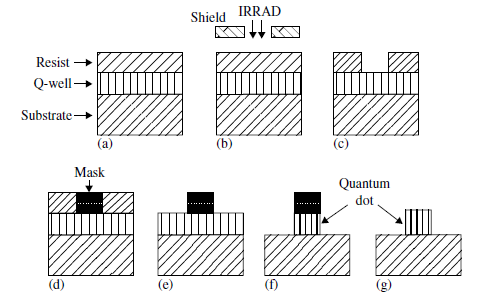

Quantum confinement occurs when the dimensions of the nanostructures are in the order of the wavelength of holes or electrons, which carry the current. In a semiconductor, these wavelengths are in the order of a micron, meaning that quantum confinement occurs at a micron or less. For a quantum dot made of a DMS (Dilute Magnetic Semiconductor) material that is a semiconductor doped with an ion having unpaired electrons such as Mn2+, a number of interesting phenomena emerge. The confinement can enhance the spin–spin exchange interaction. This means that quantum dots may have higher Curie temperatures compared to the bulk material.

A magnetic quantum dot is a ferromagnetic material in which all three dimensions are of nanometer length. Such dots can be fabricated by a top‐down process using electron beam lithography. Referring to figure, the initial step is to fabricate a quantum magnetic well such as Si:Mn on a substrate. As shown in Figure a, this is then covered by a material called a resist, which is sensitive to radiation. A typical resist consists of the polymer polymethyl methacrylate [C5O2H8]n. The sample is then irradiated by an electron beam in the region where the nanostructure will be located, as shown in Figure b. This can be done either by using a radiation mask that contains the nanostructured pattern, as shown. The radiation chemically modifies the exposed area of the resist so that it becomes soluble in a developer. The third step (Figure c) in the process is the application of the developer to remove the irradiated portions of the resist. The fourth step (Figure d) is the insertion of an etching mask into the hole in the resist, and the fifth step (Figure e) consists in lifting off the remaining parts of the resist. In step six (Figure f), the areas of the quantum well not covered by the etching mask are chemically etched away to produce the quantum structure shown in Figure f covered by the etching mask. Finally, the etching mask is removed to provide the desired quantum structure (Figure g), which is the quantum dot. This is the most common process called electron beam lithography that makes use of an electron beam for the radiation. There are other types of lithography that employ neutral atom beams (e.g., Li, Na, K, Rb, Cs), charged ion beams (e.g., Ga+), or electromagnetic radiation such as visible light, ultraviolet light, or x rays.

Article src: Physics of Magnetic Nanostructures, First Edition. Frank J. Owens, Inc. Published by John Wiley & Sons, Inc., 2015.

Random Anisotropy

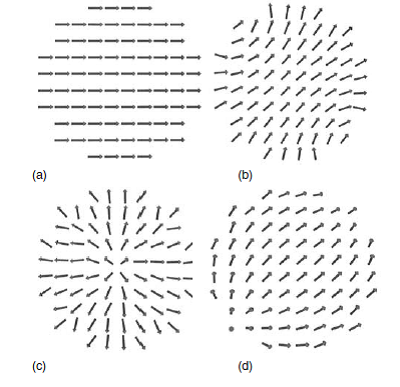

Img src

The concept of random anisotropy in continuous magnetic systems such as amorphous alloys was reviewed. It is illustrated how interparticle exchange and random anisotropy combine to affect the magnetic properties of discrete magnetic systems such as nanocrystalline alloys. In the random anisotropy situation, the effective anisotropy is reduced by averaging K1oc over the exchange length of the magnetic moments. In nanocrystalline materials, K1oc applies over the entire nanocrystal volume, and hence the appropriate length scale for the random anisotropy variation 1 is given by the thickness of the interparticle layer. The variation in magnetization direction occurs over the intergranular material between the particle surfaces if K1oc is strong compared to the anisotropy of the intergranular, amorphous matrix Kam, or over a larger length if K1oc is comparable to K1oc.

Random anisotropy can promote spatial dispersion of the local moments, and the additional presence of more than one magnetic species can lead to a rich variety of magnetic structures with dispersed parallel (speromagnetic) or dispersed antiparallel [sperimagnetic (SM)] magnetic sublattices. For smaller values of d, canted speromagnetism (& ISM) can be observed.

Alben et al. (1978) treat several fundamentals sues in amorphous ferromagnetism, notably the effects of random anisotropy on coercivity, spin wave demagnetization, and chemical versus structural disorder effects on the temperature dependence of magnetization.

Article src: Modern magnetic materials: Principles and Applications, R. C. O' HANDLEY, Massachusetts Institute of Technology, John Wiley & Sons, Inc., 2000.

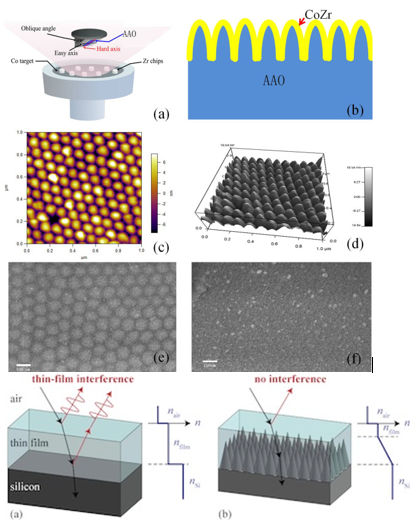

Surface anisotropy

Img src

There is the anisotropy in thin films and nanoparticles that comes from the surface. Surface anisotropy was first discussed by Neel in 1956. He estimated the magnitude as Ks ≈ 1 mJ m-2. It arises mainly from the single ion mechanism – the coupling of the surface atoms to the crystal field produced by their anisotropic surroundings. Mostly it originates in the surface monolayer which has broken symmetry, but it extends to the first few monolayers which experience structural relaxation normal to the surface. The total anisotropy of a thin film is therefore the sum of terms that scale with volume and surface area.

Surface anisotropy can also influence the magnetic configurations of ferromagnetic nanoparticles, when the exchange is not too strong. Some examples are shown in figure. These effects are unimportant in nanoparticles of 3d metals and alloys with Curie points above room temperature, but they may be significant for rare-earth alloys with low Curie points, or actinide ferromagnets like US, where the single-ion anisotropy is exceptionally strong.

Article src: Magnetism and Magnetic Materials, J. M. D Coey, Cambridge University Press, 2010.

Thin-Film Nanocomposites

A simple approach to produce exchange-coupled nanocomposites in the FePt/α-Fe and FePt/Co systems is to use multilayers of the hard and soft phases. In FePt thin films, the FePt/Fe multilayers, due to the higher degree of chemical homogeneity in their microstructure, produce better exchange coupling than the Fe/Pt multilayers. Coercivity increases with decreasing thickness of the Fe layers. Theoretical calculations predict a high anisotropy, high coercivity, and thereby an enhanced energy product of ≈ 700 kJ/m3 for 8 nm α-Fe in an aligned FePt matrix.

During the last decade, considerable effort has been made to synthesize thin-film nanocomposites based on Nd-Fe-B and FePt alloys. The nature of interlayer coupling investigated by Henkel plots revealed that, in Nd-Fe-B and FePt thin films, as in bulk composites, the coupling is dominated by exchange interactions. Sun et al. observed that the degree of this exchange coupling depends on the thickness of the soft layer.

Article src: Handbook of Nanomaterials, R. Vajtai, Springer-Verlag Berlin Heidelberg, 2013.

Thin-films

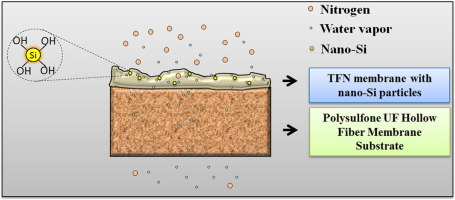

Thin-film or multilayer magnetic nanostructures have only one dimension in the nanoscale range. Magnetic and nonmagnetic layers are stacked to make heterostructured thin films, which have applications in spin valves, tunnel junctions, GMR, etc. Magnetic thin films show interesting magnetic phenomena such as perpendicular anisotropy, moment modifications at surfaces and interfaces, and thickness-dependent domain wall motion.

For thin films with perpendicular magnetic anisotropy, the saturation magnetization in the perpendicular direction is higher than that in the parallel direction. The perpendicular magnetic anisotropy in thin films is thickness dependent and vanishes with increasing film thickness, due to multidomain particle formation at larger thickness. At low thickness, Nd-Fe-B films are single domain and magnetization reversal is dominated by coherent rotation of magnetic domains, resulting in high coercivity. However, for larger thickness, the magnetization/demagnetization mechanism is different (domain wall motion) and results in low coercivity.

An ideal thin film is characterized by smooth layerby- layer growth with high degree of epitaxial order and a smooth interface. The interlayer diffusion has to be minimized, and an overlayer of immiscible elements may have to be used to obtain a smooth interface.

The technique of RF/magnetron sputtering is usually employed for Nd-Fe-B and FePt thin-film preparation. Synthesis of FePt thin films with excellent magnetic properties has also been achieved by electrodeposition.

Article src: Handbook of Nanomaterials, R. Vajtai, Springer-Verlag Berlin Heidelberg, 2013.