You simply need to know - Basics

Anisotropy is a dependence of energy level on some direction. If the magnetic moments in a material have a bias towards one particular direction (the......

Anisotropy is a dependence of energy level on some direction. If the magnetic moments in a material have a bias towards one particular direction (the easy axis) then the material is said to have uniaxial anisotropy, like cobalt. If the bias is towards many particular directions, then the material has multiple easy axes and it possesses cubic anisotropy. Cubic crystals such as iron and nickel have this property. Uniaxial and cubic anisotropy are forms of magnetocrystalline anisotropy as their properties in this respect arise from the crystalline structure of the material.

![\includegraphics[width=1.0\textwidth,clip]{images/anisotropyenergy2}](https://www.southampton.ac.uk/~rpb/thesis/img58.png)

Figure 1 Energy density due to uniaxial anisotropy as a function of the angle θ from a magnetic moment μ. The maximum energy has been normalised to zero for clarity.

![\includegraphics[width=1.025\textwidth,clip]{images/anisotropy-ce}](https://www.southampton.ac.uk/~rpb/thesis/img61.png)

Figure 2 : Normalised cubic anisotropy energy surfaces wc (θ,φ) for (left) iron and (right) nickel. The different shapes of the surfaces are a reflection of the sign of K1 -- iron has a positive K1, nickel a negative K1

The anisotropy energy in transition metal magnets arises from spin-orbit coupling.

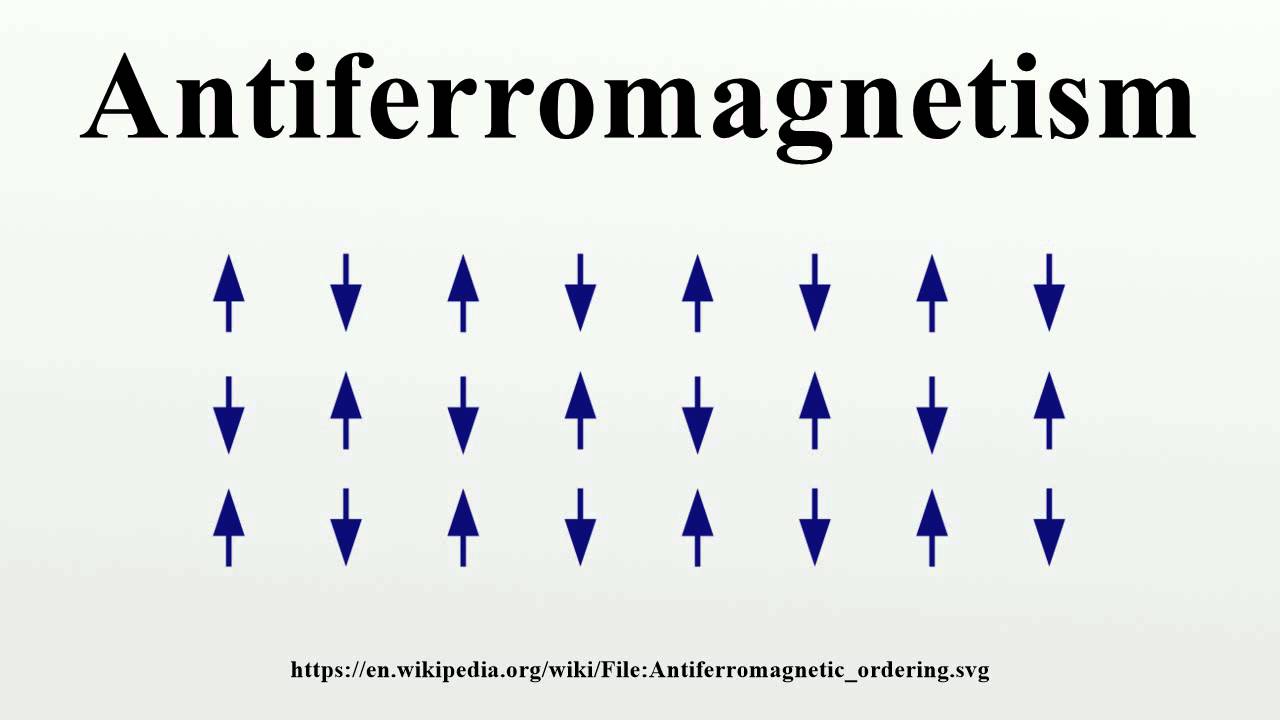

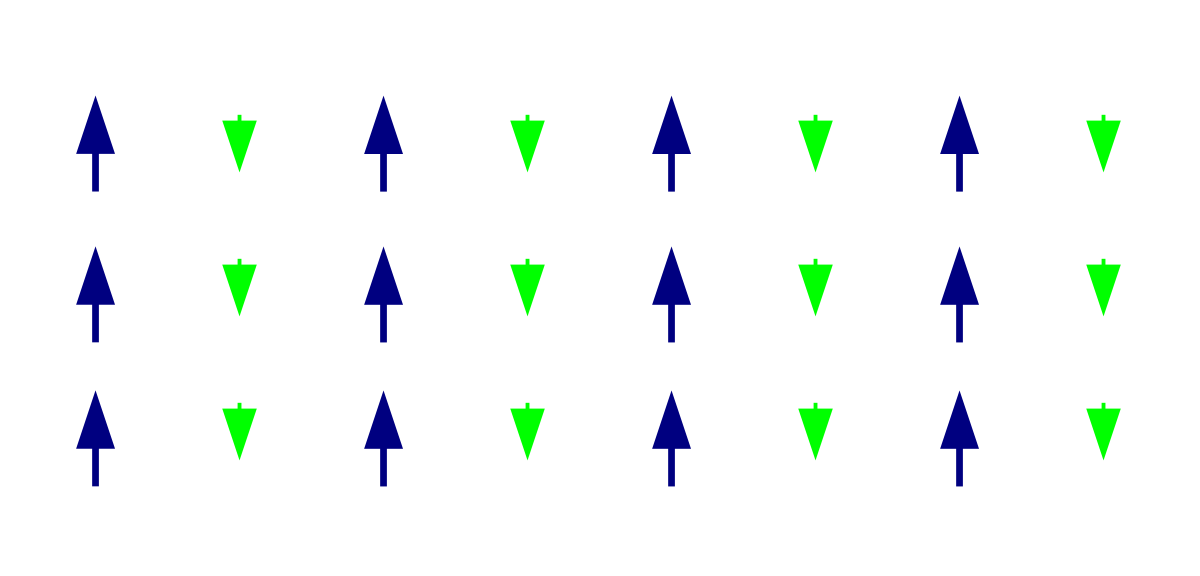

Antiferromagnetism, type of magnetism in solids such as manganese oxide (MnO) in which adjacent ions that behave as tiny magnets (in this case manganese ions, Mn2+) spontaneously align themselves at relatively......

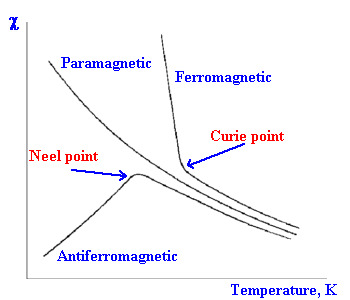

Antiferromagnetism, type of magnetism in solids such as manganese oxide (MnO) in which adjacent ions that behave as tiny magnets (in this case manganese ions, Mn2+) spontaneously align themselves at relatively low temperatures into opposite, or antiparallel, arrangements throughout the material so that it exhibits almost no gross external magnetism. In antiferromagnetic materials, which include certain metals and alloys in addition to some ionic solids, the magnetism from magnetic atoms or ions oriented in one direction is canceled out by the set of magnetic atoms or ions that are aligned in the reverse direction. This spontaneous antiparallel coupling of atomic magnets is disrupted by heating and disappears entirely above a certain temperature, called the Néel temperature, characteristic of each antiferromagnetic material. (The Néel temperature is named for Louis Néel, French physicist, who in 1936 gave one of the first explanations of antiferromagnetism.) Some antiferromagnetic materials have Néel temperatures at, or even several hundred degrees above, room temperature, but usually these temperatures are lower. The Néel temperature for manganese oxide, for example, is 122 K (−151° C, or −240° F). Antiferromagnetic solids exhibit special behaviour in an applied magnetic field depending upon the temperature. At very low temperatures, the solid exhibits no response to the external field, because the antiparallel ordering of atomic magnets is rigidly maintained. At higher temperatures, some atoms break free of the orderly arrangement and align with the external field. This alignment and the weak magnetism it produces in the solid reach their peak at the Néel temperature. Above this temperature, thermal agitation progressively prevents alignment of the atoms with the magnetic field, so that the weak magnetism produced in the solid by the alignment of its atoms continuously decreases as temperature is increased.

Coercivity, also called the magnetic coercivity, coercive field or coercive force, is a measure of the ability of a ferromagnetic material to withstand an external......

Coercivity, also called the magnetic coercivity, coercive field or coercive force, is a measure of the ability of a ferromagnetic material to withstand an external magnetic field without becoming demagnetized. An analogous property in electrical engineering and materials science, electric coercivity, is the ability of a ferroelectric material to withstand an external electric field without becoming depolarized.

Coercivity in a ferromagnetic material is the intensity of the applied magnetic field required to reduce the magnetization of that material to zero after the magnetization of the sample has been driven to saturation. Thus (normal) coercivity measures the resistance of a ferromagnetic material to becoming demagnetized. Coercivity is usually measured in oersted or ampere/meter units and is denoted HC. A larger value is the intrinsic coercivity HCi which does not take into account the negative vacuum permittivity contribution to the magnetic field B, only considering the magnetization. There may be ambiguity between the two concepts, and especially for strong magnets the difference becomes significant. The strongest rare earth magnets lose actually almost none of the magnetization at HC, and the reduction of the field to zero is almost equal to the contribution of the vacuum permittivity to the magnetic field. The normal coercivity is used to calculate the magnetomotive force, while the intrinsic coercivity is used to assess the sensitivity to demagnetization.

It can be measured using a B-H analyzer or magnetometer.

Ferromagnetic materials with high coercivity are called magnetically hard, and are used to make permanent magnets. Materials with low coercivity are said to be magnetically soft. The latter are used in transformer and inductor cores, recording heads, microwave devices, and magnetic shielding.

The critical or ordering temperature for a ferromagnetic or a ferrimagnetic material. The Curie temperature (TC) is the temperature below which there is a spontaneous......

The critical or ordering temperature for a ferromagnetic or a ferrimagnetic material. The Curie temperature (TC) is the temperature below which there is a spontaneous magnetization M in the absence of an externally applied magnetic field, and above which the material is paramagnetic.

In the disordered state above the Curie temperature, thermal energy overrides any interactions between the local magnetic moments of ions. Below the Curie temperature, these interactions are predominant and cause the local moments to order or align so that there is a net spontaneous magnetization.

Diamagnetism, kind of magnetism characteristic of materials that line up at right angles to a nonuniform magnetic field and that partly expel from their interior the magnetic field in......

Diamagnetism, kind of magnetism characteristic of materials that line up at right angles to a nonuniform magnetic field and that partly expel from their interior the magnetic field in which they are placed. First observed by S.J. Brugmans (1778) in bismuth and antimony, diamagnetism was named and studied by Michael Faraday (beginning in 1845). He and subsequent experimenters found that some elements and most compounds exhibit this “negative” magnetism. Indeed, all substances are diamagnetic: the strong external magnetic field speeds up or slows down the electrons orbiting in atoms in such a way as to oppose the action of the external field in accordance with Lenz’s law. The diamagnetism of some materials, however, is masked either by a weak magnetic attraction (paramagnetism) or a very strong attraction (ferromagnetism). Diamagnetism is observable in substances with symmetric electronic structure (as ionic crystals and rare gases) and no permanent magnetic moment. Diamagnetism is not affected by changes in temperature. For diamagnetic materials the value of the susceptibility (a measure of the relative amount of induced magnetism) is always negative and typically near negative one-millionth.

A domain wall is a term used in physics which can have similar meanings in magnetism, optics, or string theory. These phenomena can all be......

A domain wall is a term used in physics which can have similar meanings in magnetism, optics, or string theory. These phenomena can all be generically described as topological solitons which occur whenever a discrete symmetry is spontaneously broken.

In magnetism, a domain wall is an interface separating magnetic domains. It is a transition between different magnetic moments and usually undergoes an angular displacement of 90° or 180°. A domain wall is a gradual reorientation of individual moments across a finite distance. The domain wall thickness depends on the anisotropy of the material, but on average spans across around 100–150 atoms.

The energy of a domain wall is simply the difference between the magnetic moments before and after the domain wall was created. This value is usually expressed as energy per unit wall area.

The width of the domain wall varies due to the two opposing energies that create it: the magnetocrystalline anisotropy energy and the exchange energy, both of which tend to be as low as possible so as to be in a more favorable energetic state. The anisotropy energy is lowest when the individual magnetic moments are aligned with the crystal lattice axes thus reducing the width of the domain wall. Conversely, the exchange energy is reduced when the magnetic moments are aligned parallel to each other and thus makes the wall thicker, due to the repulsion between them (where anti-parallel alignment would bring them closer, working to reduce the wall thickness). In the end an equilibrium is reached between the two and the domain wall's width is set as such.

An ideal domain wall would be fully independent of position, but the structures are not ideal and so get stuck on inclusion sites within the medium, also known as crystallographic defects. These include missing or different (foreign) atoms, oxides, insulators and even stresses within the crystal. This prevents the formation of domain walls and also inhibits their propagation through the medium. Thus a greater applied magnetic field is required to overcome these sites.

Note that the magnetic domain walls are exact solutions to classical nonlinear equations of magnets (Landau–Lifshitz model, nonlinear Schrödinger equation and so on).

The exchange stiffness coefficient, Aex, represents the strength of direct exchange interactions among neighboring spins. Aex is linked to most of the magnetic properties such......

The exchange stiffness coefficient, Aex, represents the strength of direct exchange interactions among neighboring spins. Aex is linked to most of the magnetic properties such as skyrmion formation, magnetic vortex, magnetic domain wall width, and exchange length. Hence, the quantification of Aex is essential to understanding fundamental magnetic properties, but little is known for the dynamics of Aex on a sub-picosecond timescale.

The ultrafast dynamcis of Aex in an ordered magnetic state in Co/Pt ferromagnetic multilayer. The significant dynamical reduction of Aex is responsible for the dramatic increase of remagnetization time for high fluences. The analysis shows that Aex dynamically varies, strongly affecting overall ultrafast demagnetization/ remagnetization process. There are investigations which demonstrates the possibility of Aex engineering in femtosecond timescale and thereby provides a way to design ultrafast spintronic devices.

Ferrimagnetism can be thought of as a combination of ferromagnetism and antiferromagnetism because of the many similarities between them, but it has important points of......

Ferrimagnetism can be thought of as a combination of ferromagnetism and antiferromagnetism because of the many similarities between them, but it has important points of difference also. Similar to ferromagnets, ferrimagnets exhibit a spontaneous magnetic moment (i.e., a magnetic moment even in the absence of a magnetic field) and hysteresis below their Curie temperature, Tc, and behave paramagnetically above the Curie temperature. On the other hand, similar to antiferromagnets, the magnetic moments of ferrimagnets align antiparallel to one another, the difference being that the net magnetic moment is non-zero. Ferrimagnetic materials are thus differentiated from ferromagnetic and antiferromagnetic materials by the arrangement of their magnetic moments, and the dependence of the resulting magnetic properties on temperature, which depend on the types of elements in the material, its crystal structure, and microstructural processing. Ferrimagnetic materials are widely used in non-volatile memory devices such as hard drives, which utilize their ability to easily switch the spins of electrons and be magnetized. When a ferrimagnet inside a coil of conducting wire is rotate, current is generated, so they are also widely used in power motors and generators. Because ferrimagnets are electrically insulating, they are also widely used in high-frequency devices because no eddy currents are induced under AC fields. Unlike ferromagnetic materials, which are typically metals, ferrimagnetic materials are ceramics, in particular, ceramic oxides. The most widely used ferrimagnets in technological devices are materials known as ferrites. Ferrites are electrically insulating transitional-metal oxides with the general chemical formula MO·Fe2·O3, where M is a divalent ion such as Mn2+, Fe2+, Co2+, or Ni2+. Ferrites are often prepared by standard ceramic processing techniques. In the case of NiO.Fe2·O3 powders of NiO and Fe2O3 are mixed together and pressed into the desired shape before sintering (firing) at high temperature to form a dense ceramic of the desired composition. This method provides a reliable way of forming a wide variety of shapes and sizes of ferrimagnetic materials for embedding into technological devices. Ferrimagnetic materials contain magnetic moments aligned antiparallel to one another, as illustrated in the figure below, similar to antiferromagnetic materials. However, instead of having a zero net magnetic moment, different numbers of unpaired electrons in the component transition metals result do not cancel one another out, resulting in a spontaneous magnetization.

Iron, nickel, cobalt and some of the rare earths (gadolinium, dysprosium) exhibit a unique magnetic behavior which is called ferromagnetism because iron (ferrum in Latin)......

Iron, nickel, cobalt and some of the rare earths (gadolinium, dysprosium) exhibit a unique magnetic behavior which is called ferromagnetism because iron (ferrum in Latin) is the most common and most dramatic example. Samarium and neodymium in alloys with cobalt have been used to fabricate very strong rare-earth magnets. Ferromagnetic materials exhibit a long-range ordering phenomenon at the atomic level which causes the unpaired electron spins to line up parallel with each other in a region called a domain. Within the domain, the magnetic field is intense, but in a bulk sample the material will usually be unmagnetized because the many domains will themselves be randomly oriented with respect to one another. Ferromagnetism manifests itself in the fact that a small externally imposed magnetic field, say from a solenoid, can cause the magnetic domains to line up with each other and the material is said to be magnetized. The driving magnetic field will then be increased by a large factor which is usually expressed as a relative permeability for the material. There are many practical applications of ferromagnetic materials, such as the electromagnet. Ferromagnets will tend to stay magnetized to some extent after being subjected to an external magnetic field. This tendency to "remember their magnetic history" is called hysteresis. The fraction of the saturation magnetization which is retained when the driving field is removed is called the remanence of the material, and is an important factor in permanent magnets. All ferromagnets have a maximum temperature where the ferromagnetic property disappears as a result of thermal agitation. This temperature is called the Curie temperature. Ferromagntic materials will respond mechanically to an impressed magnetic field, changing length slightly in the direction of the applied field. This property, called magnetostriction, leads to the familiar hum of transformers as they respond mechanically to 60 Hz AC voltages.

For understanding the hard magnetic materials, we have to know certain terms. They are as follows:

- Coercivity: The capability of a ferromagnetic material to hold up (resist)......

For understanding the hard magnetic materials, we have to know certain terms. They are as follows:

- Coercivity: The capability of a ferromagnetic material to hold up (resist) a peripheral magnetic field without getting demagnetized.

- Retentivity (Br): It is the amount of magnetism that a ferromagnetic material can maintain even after the magnetic field is decreased to zero.

- Permeability: It is used to determine how a material reacts to the applied magnetic field.

- Magnetic materials are mainly classified (based on the magnitude of coercive force) into two sub domains – hard magnetic materials and soft magnetic materials,

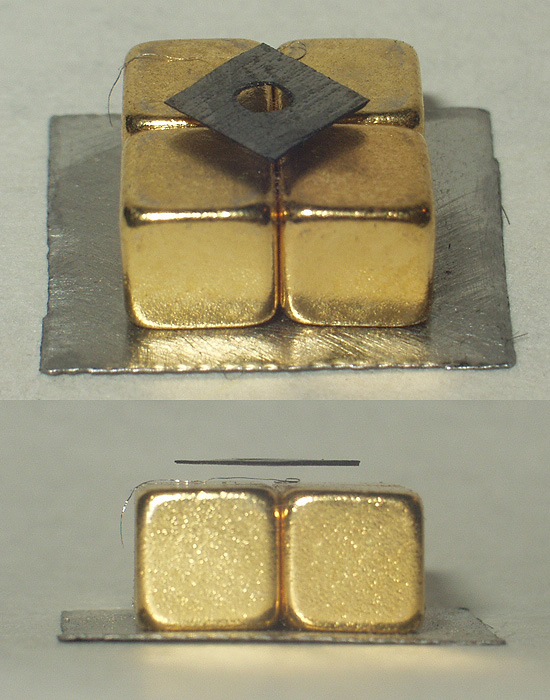

Now, we can define hard magnetic materials. These materials are really hard in the basis that it is very difficult to get magnetised. The reason is that the domain walls are motionless owing to crystal defects and imperfections.

But if it gets magnetised, it will be permanently magnetised. That is why; it is also called as permanent magnetic material. They have coercive force greater than 10kA/m and have high retentivity. When we expose a hard magnet to an external magnetic field for the first time, the domain grows and rotates to align with the applied field at the saturation magnetization. After that, the field is removed. As a result, the magnetization is somewhat reverted but it does not track the magnetization curve any longer. A certain amount of energy (Br) is stored in the magnet and it becomes permanently magnetized.

Properties of Hard Magnetic Materials

- Utmost retentivity and coercivity.

- Value of energy product (BH) will be large.

- The shape of BH loop is nearly rectangle.

- High hysteresis loop.

- Small initial permeability.

The properties of some important permanent magnetic material are shown in the table below.

| Hard magnetic materials | Coercivity (Am-1) | Retentivity (T) | BHmax(Jm-1) |

| Alnico 5 (Alcomax) (51Fe, 24 Co,14 Ni, 8Al, 3Cu) | 44,000 | 1.25 | 36,000 |

| Alnico 2 (55Fe, 12Co, 17Ni, 10Al, 6Cu) | 44,800 | 0.7 | 13,600 |

| Chrome steel (98Fe, 0.9Cr, 0.6 C, 0.4Mn) | 4,000 | 1.0 | 1,600 |

| Oxide (57Fe, 28 O, 15Co) | 72,000 | 0.2 | 4,800 |

Some important hard magnetic materials are the following:

Steel

The carbon steel have large hysteresis loop. Due to any shock or vibration, they lose their magnetic properties rapidly. But tungsten steel, chromium steel and cobalt steel have high energy product.

Alnico

It is made up of aluminium, nickel and cobalt to boost to improve the magnetic properties. Alnico 5 is the most important material used to create permanent magnet. The BH product is 36000 Jm-3. It is used in high temperature operation.

Rare-Earth Alloys:

SmCo5, Sm2Co17, NdFeB etc.

Hard Ferrites or Ceramic magnets (like Barium Ferrites):

These materials can be powdered and used as a binder in plastics. The plastics made by this method are called plastic magnet.

Bonded Magnets:

It is used in DC motors, Stepper motors etc.

Nanocrystalline hard magnet (Nd-Fe-B Alloys):

The small size and weight of these material make it to use in medical devices, thin motors etc.